Home / All / CNC Machining Parts /

Customized High Precision Anodizing CNC Steel Milling for Diffuser Parts

Customized High Precision Anodizing CNC Steel Milling for Diffuser Parts

| Categories | CNC Machining Parts |

|---|---|

| Brand | Zehan CNC Machining Parts Service |

| Model | OEM |

| Material | steel,brass,aluminum,stainless steel |

| Process | CNC machining,Turning,Milling,Hot forging,Cold heading |

| Requirements | No burr,Scratches,Dents,Pits,Oil stain |

| Package | Bulk packing , Cartons, Pallets, Wooden case |

| MOQ | 50 pcs |

| FOB Port | Qingdao |

| Lead time | 15-20 days. |

| Shipping | by sea, by air, by DHL, UPS, Fedex , TNT & etc. |

| Main Export Markets | USA, Canada ,Britain , Belgium , Germany, Mexico, Netherlands, Japan , The United Arab Emirates |

| Payment method | T/T, PayPal , Western Union |

| Unit Price | US $ 3-5 / piece |

| FOB port | Qingdao Port |

| Terms of Payment | L/C, D/A, D/P, Western Union |

| Update Time | Apr 19,2025 |

Detail Information

Customized High Precision Anodizing CNC Steel Milling for Diffuser Parts

|

Product Name

|

Customized High Precision Anodizing CNC Steel Milling for Diffuser Parts

|

||

|

Quality Assurance

|

We promise 100% inspection before shipping

|

||

|

Material

|

Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc.

|

||

|

Brass Alloy:3600/ 3602 / 2604 / H59 / H62 / etc.

|

|||

Stainless Steel Alloy:303 / 304 / 316 / 412 / etc. | |||

Steel Alloy:Carbon Steel / Die Steel / etc. | |||

Other Special Materials:Lucite / Nylon / Bakelite / etc. | |||

We handle many other type of materials. Please contact us if your required material is not listed above. | |||

Surface Treatment | Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting and so on. | ||

Inspection Tools | Projector etc. | ||

File Format | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. | ||

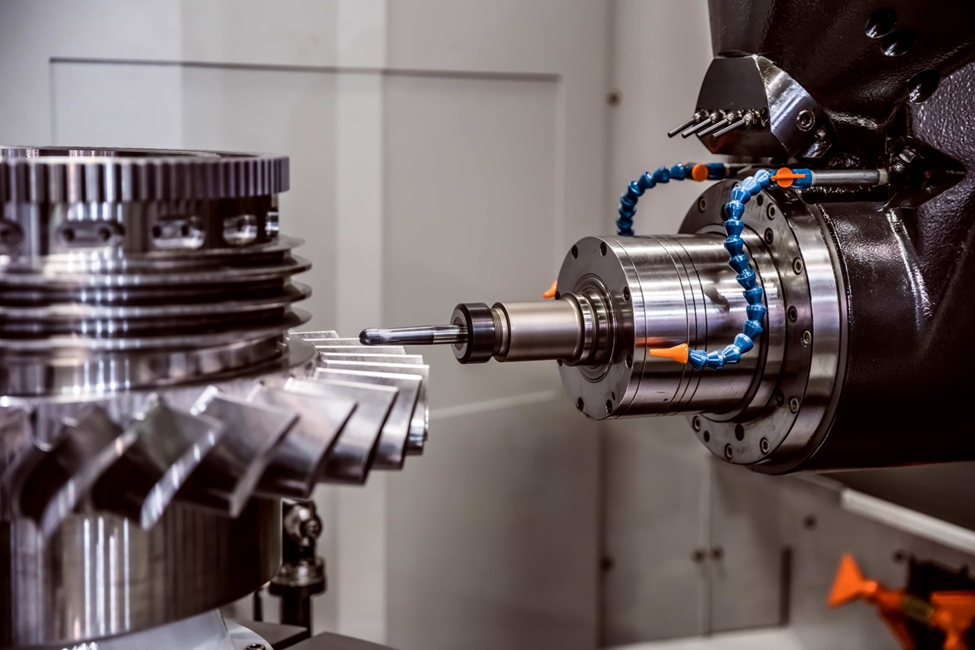

Machining Equipments | Machining Center / CNC Lathes / Grinding Machines / Milling Machines / Lathes / Stamping Machines/ Full Automatic Lathe /etc. | ||

What is Electronic Edge Finder and it's working mechinism?

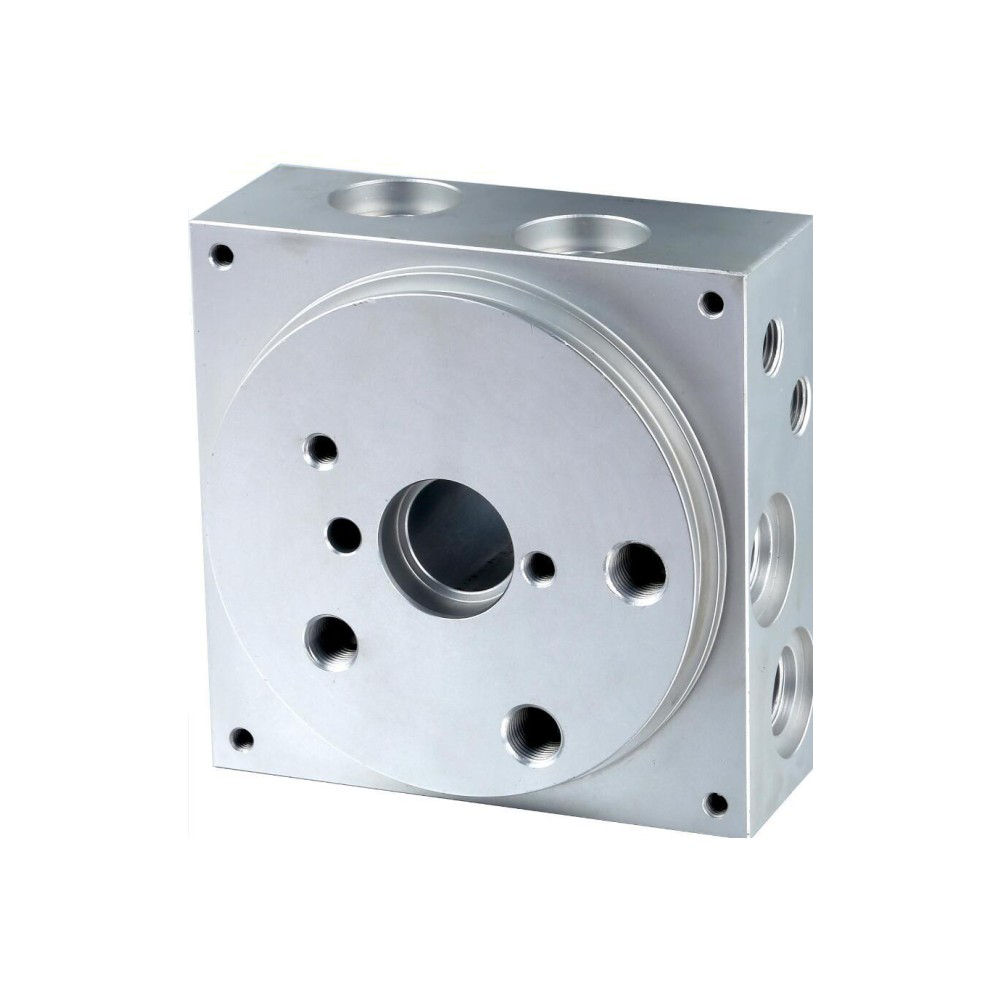

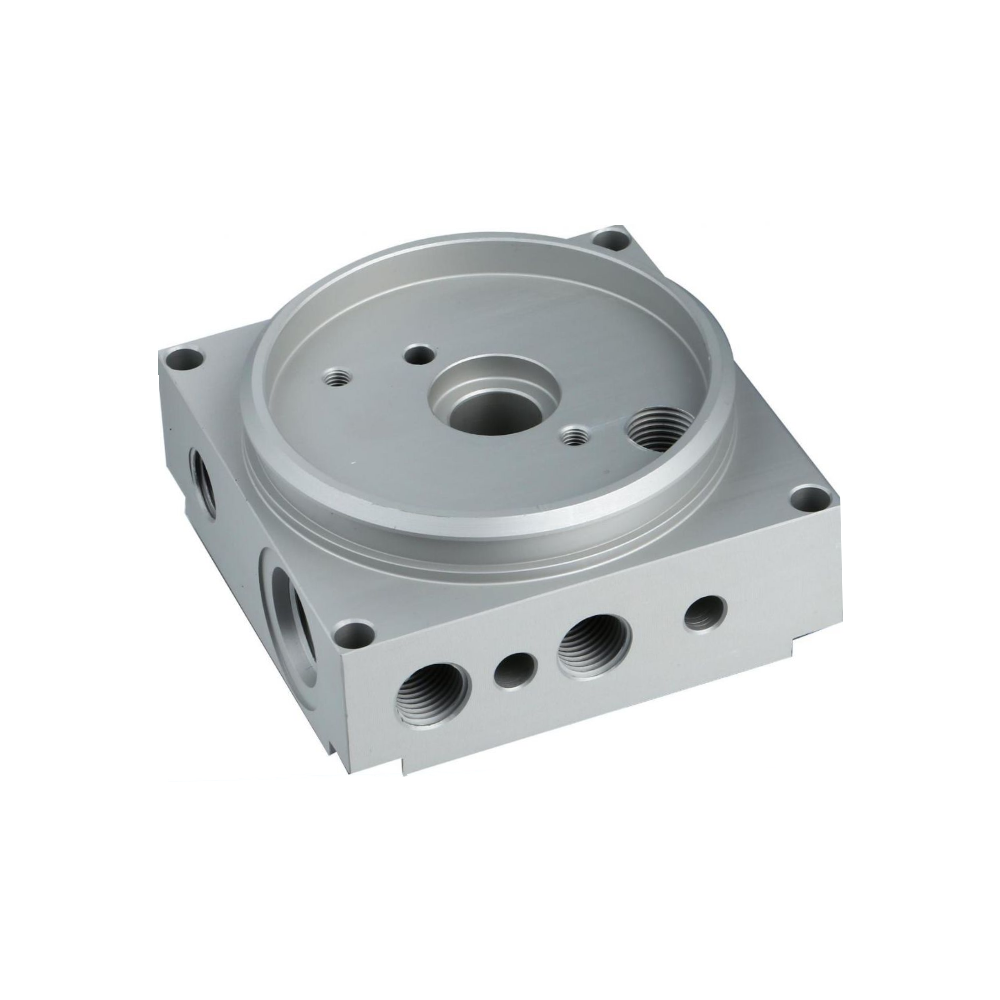

Hydraulic Manifold Blocks are also called the Hydraulic Valve Blocks.

The function of Hydraulic Manifold Blocks is to arrange a collection of valves and accessories to form a hydraulic control system.

They are all machined parts that act as junctions between components in a Hydraulic System to regulate the fluid flow. Some of the elements that utilize these blocks include pumps and actuators. The design of Hydraulic Manifolds allows an operator to monitor how fluid moves in different parts just as a switchboard does with an electric current. A good example of how a manifold works is in a backhoe loader. In this machine, there is a front and back bucket with telescopic arms, where the fluid flows. A Manifold in this instance is attached to the levers, and when operated, it diverts, turns off or turns on the flow to the arms. The operation of the Manifold determines how it behaves.

Also, the manifold Blocks comprise interconnections of hydraulic valves.

Please send your message to us

- Name

- Tel

- *Title

- *Content

- KEEP UP TO DATE

- Sign up for our newsletter and follow us on social media

subscription

NAVIGATION

LATEST POSTS

- Laser Cutting ServicesAug 16,2020

- What Is Metal Stamping?Aug 15,2020

- Sheet Metal Stamping ProcessAug 14,2020

ZEHAN MACHINERY

ZEHAN MACHINERY