- 3D Printing Service

What is 3D Printing ?

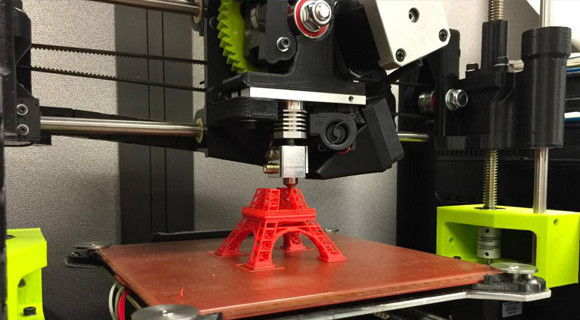

3D printing is a kind of rapid prototyping technology, also known as additive manufacturing or laminated manufacturing. It refers to any process of printing a three-dimensional object. 3D printing is mainly a process of continuous addition and stacking raw materials under computer control. 3D printed content may be derived from 3D models or other electronic data. The printed 3D object can be any shape and with any geometric features. The 3D printer is also a kind of industrial robot. It is a technique to construct an object by layer-by-layer printing based on a digital model file and using an adhesive material such as powder metal or plastic.

What is the Application Range of 3D Printing ?

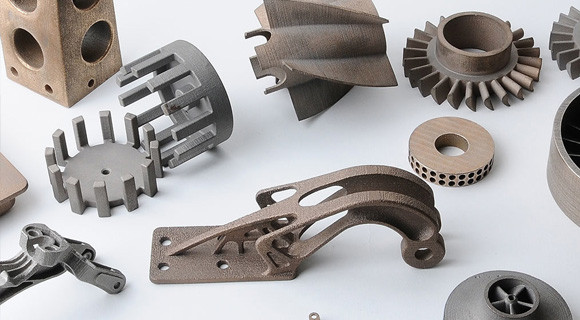

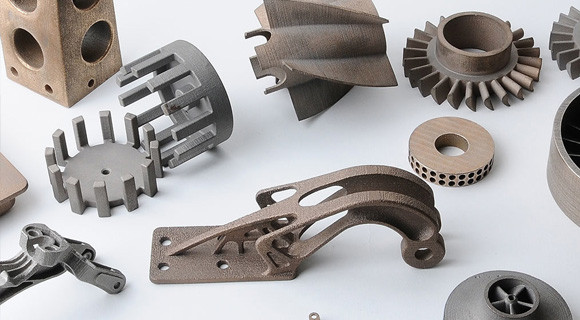

3D printing is usually done by using a digital technology material printer. It is often used to create model in the fields of mould manufacturing and industrial design, then it is gradually being used for direct manufacture of some products, there have been parts printed with this technology. The technology is used in the jewelry, footwear, industrial design, construction, engineering and construction (AEC), automotive, aerospace, dental and medical industries, education, geographic information systems, civil engineering, firearms and other fields.

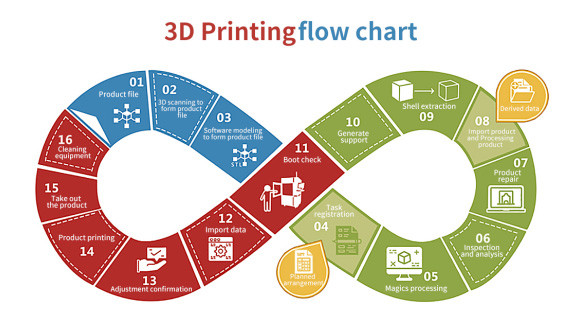

What is the Process of 3D Printing ?

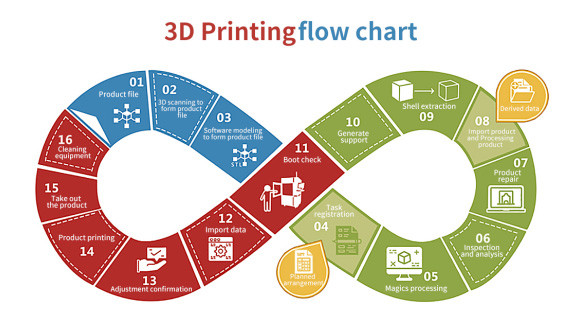

1. Design Process of 3D Printing

The design process of 3D printing is: First to establish a model through computer aided design (CAD) or computer animation modeling software, then "divide" the built 3D model into a layer-by-layer section to guide the printer to print layer by layer.

The standard file format for designing collaboration between software and printers is the STL file format. An STL file uses a triangular face to roughly simulate the surface of an object. The smaller the triangular face is, the higher the surface resolution it produces.

PLY is a scanner that generates a three-dimensional file by scanning, which generates VRML or WRL files that are often used as input files for full-color printing.

2. Print Procedure

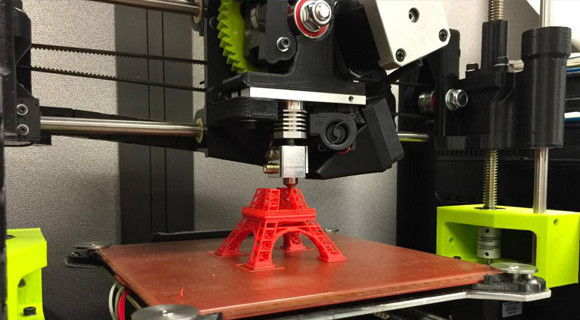

By reading the cross-sectional information in the document, the printer prints the sections layer by layer with a liquid, powder or sheet material, and then bonds the layers in various ways to create an entity. This technique is characterized by its ability to produce objects of almost any shape.

The thickness of the cross section (that is the Z direction) and the resolution of the plane direction (that is the X-Y direction) which printed by the printer are calculated in terms of dpi (pixel per inch) or micron. The typical thickness is 100 microns that is 0.1 millimeters, there are also some printers such as the Objet Connex series and the 3D Systems' ProJet series can print a thin layer of 16 micron, but it can also print out the resolution similar to that of the laser printer in plane direction. The diameter of printed “ink drops” are typically 50 to 100 microns. It takes between a few hours and a few days to create a model using traditional methods, depending on the size and complexity of the model. However, 3D printing technique can reduce the time to several hours, of course this is determined by the performance of the printer and the size and complexity of the model. We can produce large numbers of polymer products at a lower cost with traditional manufacturing techniques such as injection molding, while 3D printing technology helps us to produce relatively small quantities of products in a faster, more flexible, and lower cost manner. A desktop-sized 3D printer can meet the needs of the designer or concept development team to create a model.

3. Finishes of 3D Printing

The resolution of current 3D printers is sufficient for most applications (the curved surface may be rough, like the saw tooth on the image), you can get higher resolution items by using the following methods: First use the current 3D printer to make a slightly larger object then slightly polished the surface to get a smooth "high resolution" item.

Some technologies can print on multiple materials simultaneously. Some techniques also use supports during the printing process. For example, when printing some objects with upside down, you need to use something that is easy to remove (such as soluble things) as a support.development team to create a model.

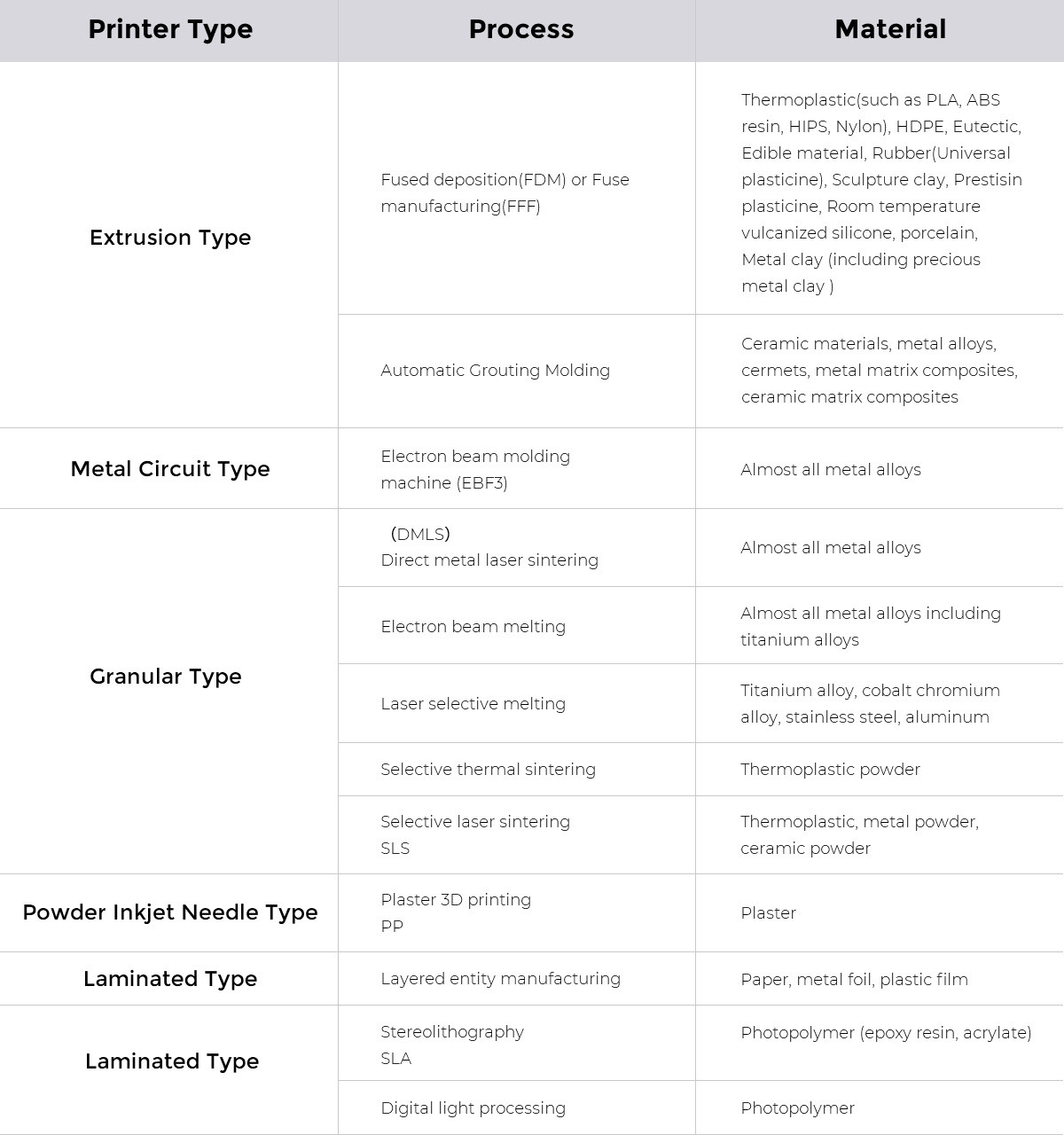

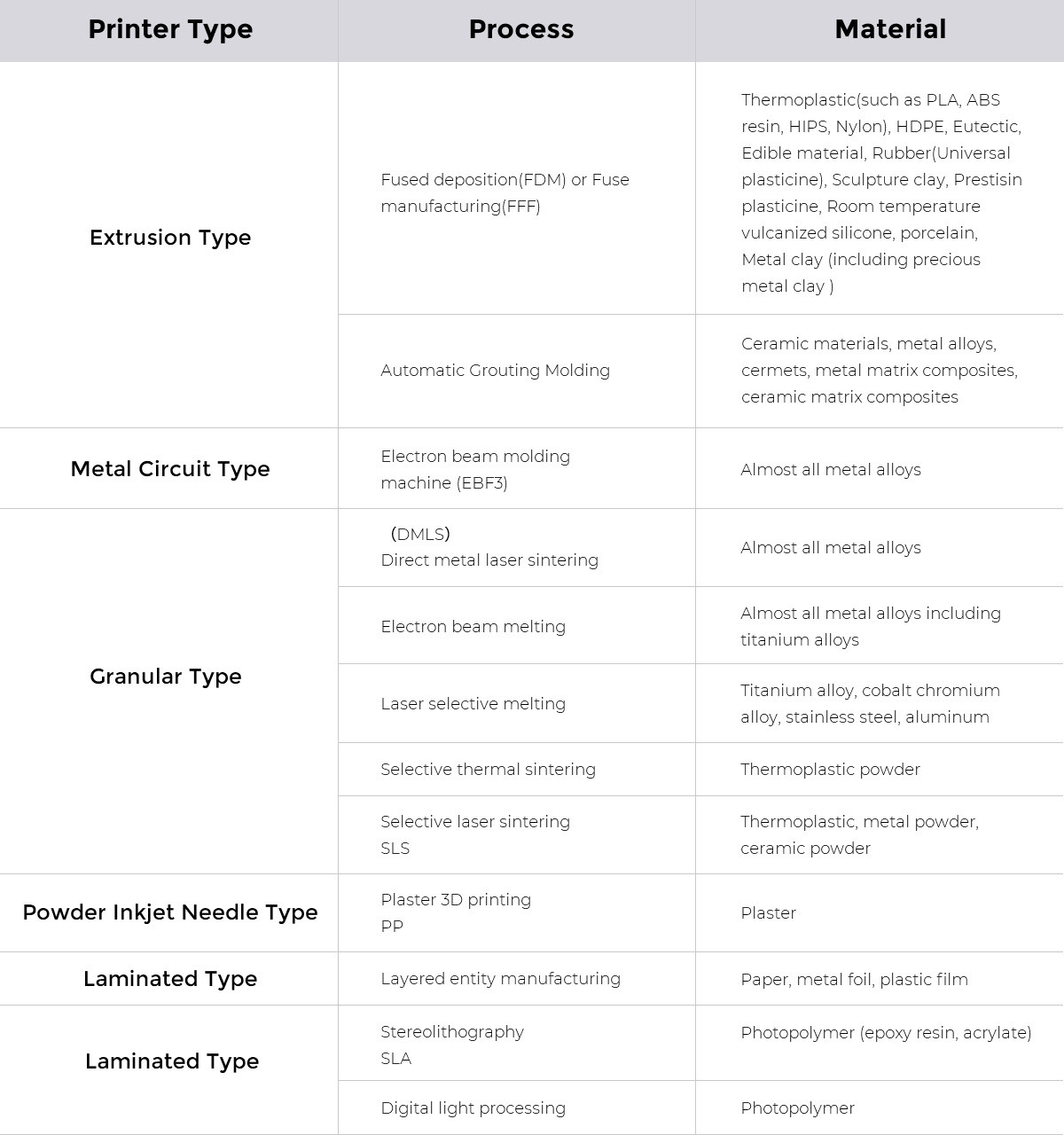

How Many Kinds of 3D Printer Are Available in the Market ?

ZEHAN MACHINERY

ZEHAN MACHINERY