- Stamping Service

ZH Stamping Service

ZH has a 20-year stable stamping supply chain system with complete stamping production line. The equipment stamping capacity is 0.5T-315T, which can provide high-precision molds according to product design requirements. The mould can be used for metal stamping of brass, steel, aluminum, stainless steel and so on.

What Is Stamping?

Stamping processing is the production technology of product parts with certain shape, dimension and performance by special stamping equipment, which directly deforms the sheet or strip in the mold.

Three Elements of Metal Stamping

Requirements for stamping materials

1 .The thickness is accurate and uniform.

2 .The surface is smooth, no spots, no flaws, no scratches, no surface cracks, etc.

3 .The yield strength is uniform and there is no obvious directionality.

4. Uniform elongation is high.

5. The yield ratio is low.

6. Low work hardening.

In actual production, usually use the process test similar to the stamping process, such as the drawing performance test and the bulging performance test, which is used to test the punching performance of the material to ensure the quality of the finished product and high qualification rate.

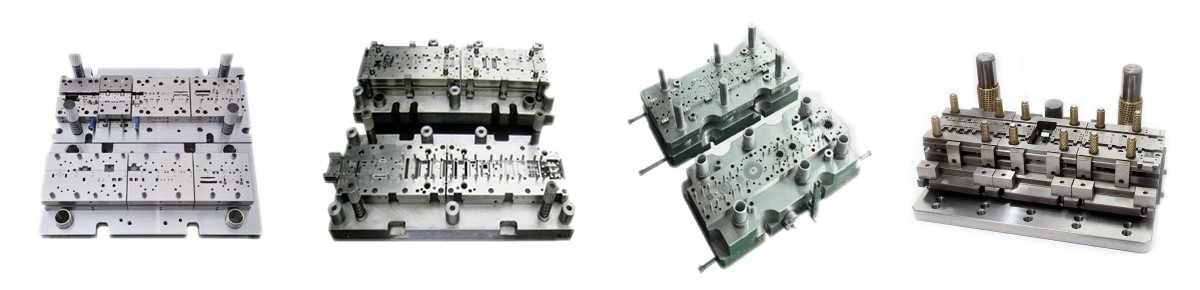

Requirements for Stamping Moulding & Dies

The precision and structure of the mold directly affect the forming and precision of the stamping. Molds manufacturing costs and longevity are important factors influencing the cost and quality of stampings. Standardization of mold bases, formwork, guides and development of simple molds (for small batch production), composite molds, multi-station progressive molds (for mass production), and the development of rapid mold change devices to reduce the workload of stamping production preparation and shortening the preparation time, the advanced stamping technology suitable for mass production can be reasonably applied to small batch and multi-variety production.

Special Stamping Equipment

Mechanical presses are generally used. Centered on modern high-speed multi-station mechanical presses, equipped with unwinding, leveling, finished product collection, conveying and other machinery as well as mold libraries and rapid mold change devices, and using computer program control, can form a high-productivity automatic stamping production line.

ZEHAN MACHINERY

ZEHAN MACHINERY