- Precision Casting Service

Zehan Precision Casting Service

The lost wax method is very suitable for producing precision castings with complex shapes and high dimensional accuracy & quality. In addition, it offers a large freedom in both design and material choice of your desired castings. Precision castings are known as the highest quality castings available on the market.

Zehan can provide brass, steel, aluminum, stainless steel precision casting and precision casting mold services.

What Is Precision Casting?

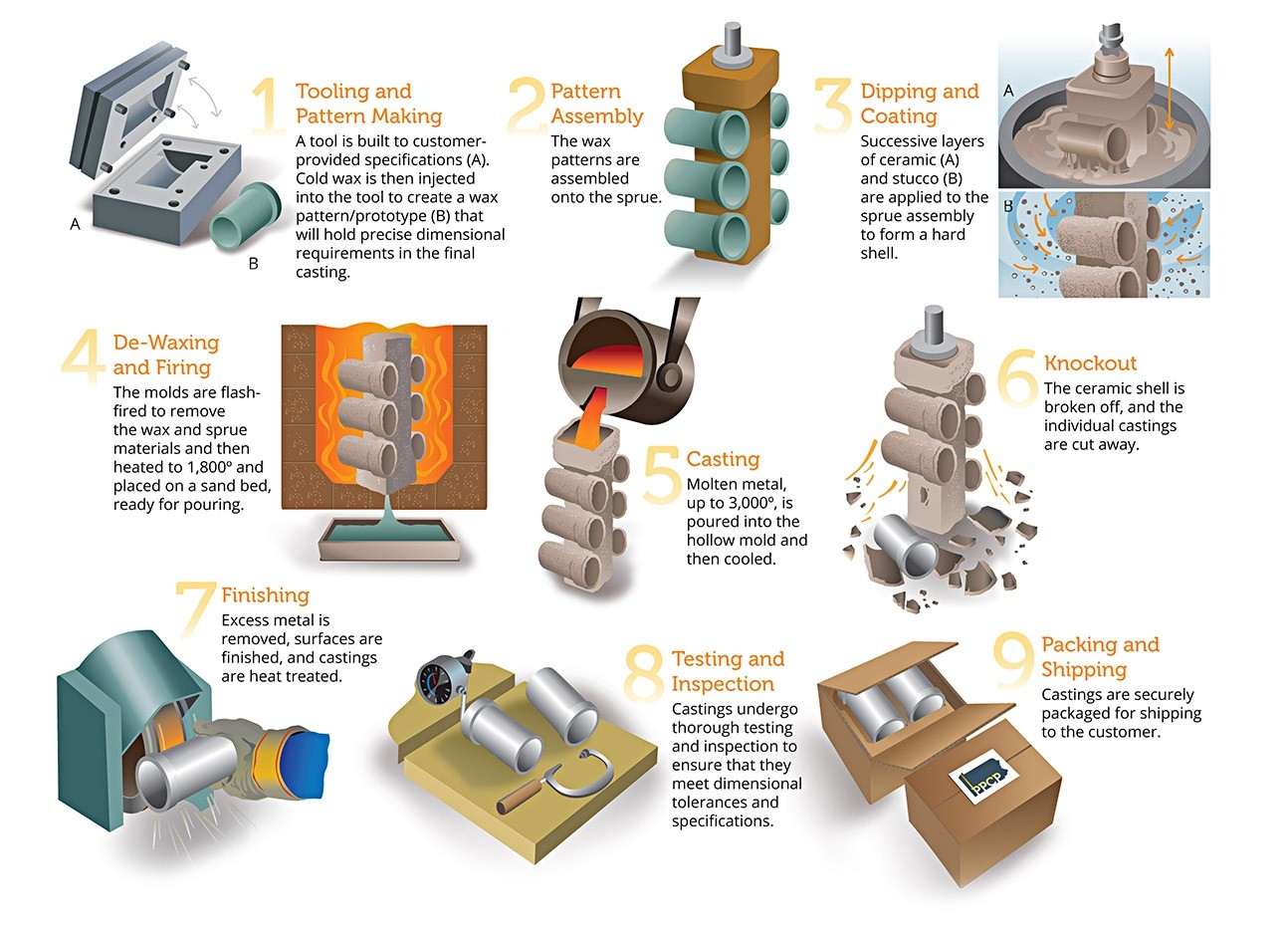

Precision casting, also called investment casting, refers to the general term for the process of obtaining precision-sized castings. Compared with the traditional sand casting process, the castings obtained by precision casting have more precise dimensions and better surface finish. It includes: investment casting, ceramic casting, metal casting, pressure casting, lost foam casting.

What Is Precision Casting Process?

The casting production process is generally so that it can be divided into Pressure wax, making shell, casting, post-treatment, inspection.Pressure wax (Shot wax and making the wax mold)---repair wax----wax inspection----wax tree (wax mold group tree)---shell (dip slurry, sand, dip slurry again, finally Mould shell air-drying)--- dewax (steam dewax)---- bake mold shell --Chemical analysis--casting (casting steel water in the mold shell)----vibration shelling---casting part and pouring Rod cutting separation----grinding sprue---initial inspection (blank inspection)--- ball blast -----cnc machining-----polishing---finish inspection--- entering warehouse.

What Factors Can Affect Precision Casting Quality ?

Usually, the dimension accuracy of precision casting parts is affected by casting parts structure, materials, mold, shell, casting and bake etc. any one of Link setting and unreasonable operation will change the contraction percentage of casting parts thus cause the deviation of casting part dimensions and precision requirement. the following factor will create accuracy defects of precision casting part dimensions:

(1)influence of casting part structure: a. the wall thickness of casting part is thick, contraction percentage large, the wall thickness of casting part is thin, contraction percentage small. b. free contraction percentage large, hinder contraction percentage small.

(2)The effect of casting materials: a. The higher the carbon content in the material, the contraction percentage of line is smaller. The lower the carbon content, the contraction percentage of line is bigger. b. casting contraction percentage of common material is as following: casting contraction percentage K=(LM-LJ)/LJ X 100%, LM is mold cavity dimensions, LJ is casting part dimensions. The following factor affect the K: wax mold K1.casting part structure K2.alloy type K3. pouring temperature K4.

(3)The mold affect for the casting part contraction percentage: a. the effect of shot wax temperature, Shot wax pressure, preservation pressure time on the size of the investment the most obvious is shot wax temperature, followed by Shot wax pressure. preservation pressure time has little effect for the final size of the fusible pattern after the guarantee fusible pattern forming. b. the contraction percentage of wax material about is 0.9-1.1%. c. when the fusible pattern is stored, it will produce shrinkage further and shrinkage value about is 10% of total shrinkage amount. but after 12 hours of storage, the investment size is substantially stable. d. The radial shrinkage of the wax mold is only 30-40% of the shrinkage in the longitudinal direction, and the effect of the wax temperature on the free shrinkage is far greater than the effect on the resistive shrinkage (the optimum wax temperature is 57-59 ° C, The higher the temperature, the greater the shrinkage).

(4)Influence of shell material: Zircon sand, zircon powder, Shangdian sand, Shangdian powder, because of its small expansion coefficient, is only 4.6×10-6/°C, so it can be ignored.

(5) Effect of shell roasting: Since the coefficient of expansion of the shell is small, when the shell temperature is 1150 ° C, it is only 0.053%, so it can be neglected.

(6) Effect of casting temperature: The higher the pouring temperature, the larger the shrinkage rate, the lower the pouring temperature and the smaller the shrinkage rate, so the pouring temperature should be appropriate.

ZEHAN MACHINERY

ZEHAN MACHINERY